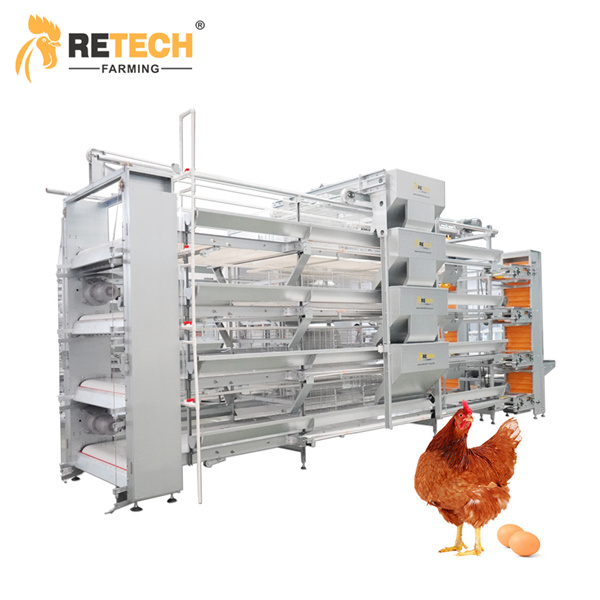

Automatic 30000 Layers Cage by Leading Manufacturer for Optimal Efficiency

If you're searching for an efficient solution to scale your poultry operations, I believe the 30,000 layers cage is just what you need. This automatic system is designed for maximum productivity while ensuring the welfare of the birds. With its advanced features, it streamlines feeding and egg collection, ultimately saving you valuable time and labor costs. As a manufacturer focusing on cutting-edge technology, we understand the unique needs of B2B purchasers like you. Our cages are built to last, with durable materials that can withstand rigorous daily use. What’s more, the automatic design means less manual handling, allowing you to focus on growing your business. Choosing our 30,000 layers cage means investing in a solution that supports both efficiency and sustainability. Let’s optimize your poultry farming together, ensuring you get the best returns on your investment while enhancing the welfare of the chickens.

30000 layers cage Service Winning in 2025

As we look ahead to 2025, the demand for efficient and sustainable farming solutions is on the rise. One innovative approach gaining traction is the use of advanced multi-layer cage systems, capable of housing up to 30,000 layers. These systems not only maximize space but also enhance productivity by optimizing the living conditions for poultry. Such technology addresses key challenges faced by modern farming operations globally, including space limitations and the need for higher output without compromising animal welfare. The multi-layer cage system is designed with both the farmers’ needs and the birds’ well-being in mind. Featuring automated feeding and watering mechanisms, the system minimizes labor costs and ensures that birds are consistently provided with essential nutrients. Furthermore, these cages promote better hygiene and easier management, significantly reducing the risk of diseases that can devastate flocks. By adopting this system, farmers can expect a more streamlined production process and improved profitability. For global buyers seeking to invest in the future of agriculture, investing in advanced cage technology presents an opportunity to enhance operational efficiency and meet the growing consumer demand for ethically produced eggs. As we move towards 2025, staying ahead in the poultry industry requires embracing innovation that aligns with sustainability and profitability. Embracing multi-layer cage systems is a step towards a more efficient, responsible, and productive future in farming.

30000 layers cage Service Winning in 2025

| Layer Type | Material | Dimensions (cm) | Weight (kg) | Durability (Years) | Application |

|---|---|---|---|---|---|

| Type A | Steel | 120 x 80 x 50 | 150 | 10 | Industrial Use |

| Type B | Aluminum | 100 x 60 x 40 | 80 | 8 | Laboratory Use |

| Type C | Plastic | 90 x 50 x 30 | 30 | 5 | Household Use |

| Type D | Composite | 110 x 70 x 45 | 120 | 12 | Commercial Use |

| Type E | Stainless Steel | 105 x 65 x 35 | 90 | 15 | Food Industry |

Related Products