Optimal Egg Laying Cage Size for Automatic Systems by Trusted Manufacturers

When it comes to optimizing your poultry production, choosing the right egg laying cage size is crucial. I’ve found that finding a balance between space and efficiency can make all the difference in egg production rates. Our cages cater to automatic systems, ensuring your workforce is minimized while maximizing output. As a manufacturer with years of experience, I understand the nuances of what you need for your operation—durability, optimal sizing, and ease of maintenance are key. Imagine a setup where your hens are comfortable and productive, leading to better quality eggs. I’ve personally seen how the right cage size can enhance their wellbeing and affect their laying patterns positively. Let’s partner up to elevate your poultry farm's efficiency. You'll see the results we promise!

egg laying cage size in 2025 Where Innovation Meets 2025

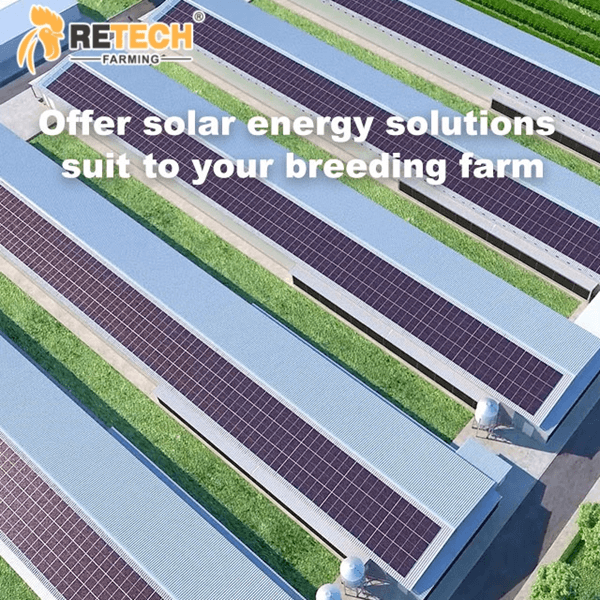

In 2025, the egg-laying cage industry is poised for groundbreaking innovation, as producers increasingly seek to balance productivity with sustainability. The optimal cage size will be pivotal in ensuring hen welfare while maximizing egg output. Recent advances in design technology have led to a focus on adjustable cage systems that can be tailored to specific farm requirements. These systems not only enhance the living conditions of the hens but also improve operational efficiency, allowing farmers to adapt to changing market demands. The global market is seeing a shift towards environmentally friendly practices, prompting manufacturers to integrate sustainable materials and energy-efficient designs into their equipment offerings. As a result, smart technology will play a crucial role in the future of egg-laying cages, offering real-time monitoring of environmental conditions, feed management, and health assessment. This innovation will not only help farmers optimize production but also align with consumer demand for ethically sourced eggs, thereby improving market competitiveness. Looking ahead, procurement strategies must evolve to incorporate these innovative solutions. Suppliers must assess the versatility of cage designs, taking into consideration factors such as space optimization and ease of maintenance. As the industry continues to embrace technological advancements, global buyers are encouraged to remain informed and engaged with suppliers who prioritize welfare, sustainability, and efficiency in their offerings, ensuring that they stay ahead in the rapidly changing agricultural landscape of 2025.

Egg Laying Cage Size in 2025: Where Innovation Meets

| Cage Type | Size (H x W x L, cm) | Capacity (Birds) | Material | Features |

|---|---|---|---|---|

| Model A | 150 x 75 x 200 | 40 | Galvanized Steel | Automatic feeders |

| Model B | 170 x 90 x 210 | 50 | Aluminum | Ventilation system |

| Model C | 200 x 100 x 220 | 60 | Stainless Steel | Eco-friendly design |

| Model D | 180 x 85 x 200 | 55 | Composite Material | Hygienic features |

Related Products