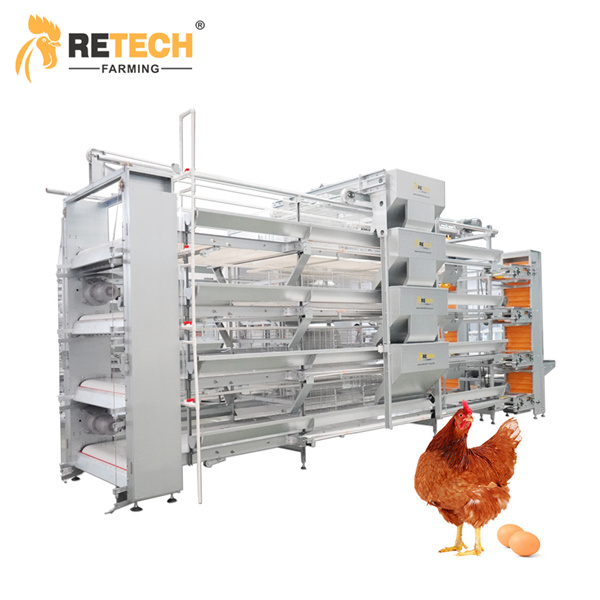

Automatic Kenya Chicken Cage Manufacturer for Efficient Poultry Farming

When choosing a solution for your poultry farming, the Kenya chicken cage has really impressed me with its efficiency and functionality. I’m all about automating processes, and these cages do just that – they maximize space while ensuring the chickens are comfortable and productive. As a manufacturer committed to quality, I've found these cages sturdy yet easy to manage. The automatic feeding system has been a game changer, allowing me to focus on growing my business instead of manual tasks. They streamline operations, reduce labor costs, and improve overall productivity. If you’re serious about enhancing your poultry operation, the Kenya chicken cage could be just what you need. The design promotes optimal chicken growth and health, ensuring your investment pays off in the long run. Partnering with a reliable supplier can also make a huge difference in your success. Feel free to reach out and discuss what the Kenya chicken cage can do for your business!

Kenya chicken cage Trusted by Pros Winning in 2025

As the global poultry industry continues to evolve, Kenya has emerged as a pivotal player, particularly with the advent of innovative chicken cage technologies. The demand for efficient, sustainable, and high-yield farming solutions has surged, and professionals in the field are turning to advanced cage systems that promise enhanced productivity and animal welfare. In 2025, we expect to see these technologies playing a central role in transforming poultry farming in Kenya and beyond, enabling farmers to meet the rising consumer demand for chicken. The key to success in this dynamic market lies in employing reliable and trusted chicken cage systems that facilitate optimal growth conditions for the birds. These modern cages not only maximize space usage but also improve cleanliness and reduce disease transmission. Professionals who have embraced these innovations report significant improvements in their operations, such as increased production rates and lower mortality rates. By investing in quality solutions, farmers can ensure that they are not just meeting current requirements but are also prepared for future challenges. As the global community continues to prioritize sustainability and animal welfare, the importance of choosing the right equipment cannot be overstated. Farming professionals across the globe are recognizing that the future of poultry farming relies on adopting proven technologies that lead to efficiency and profitability. The insights gained from those already succeeding with advanced chicken cage systems will guide newcomers in navigating this burgeoning market. Embracing these innovations will ultimately position them as leaders in a competitive landscape, where growth and success are increasingly reliant on smart, responsible farming practices.

Kenya Chicken Cage Trusted by Pros Winning in 2025

| Model | Capacity (Chickens) | Material | Dimensions (LxWxH) | Weight (kg) | Features |

|---|---|---|---|---|---|

| Cage Model A | 100 | Galvanized Steel | 2m x 1m x 1.5m | 50 | Ventilated, Easy Clean |

| Cage Model B | 150 | Stainless Steel | 2.5m x 1.2m x 1.6m | 60 | Automatic Feeder, Insulated |

| Cage Model C | 200 | Recycled Plastic | 3m x 1.5m x 1.7m | 75 | Eco-Friendly, Modular Design |

| Cage Model D | 250 | Wooden Frame | 3m x 2m x 1.5m | 80 | Insulated, Customizable |

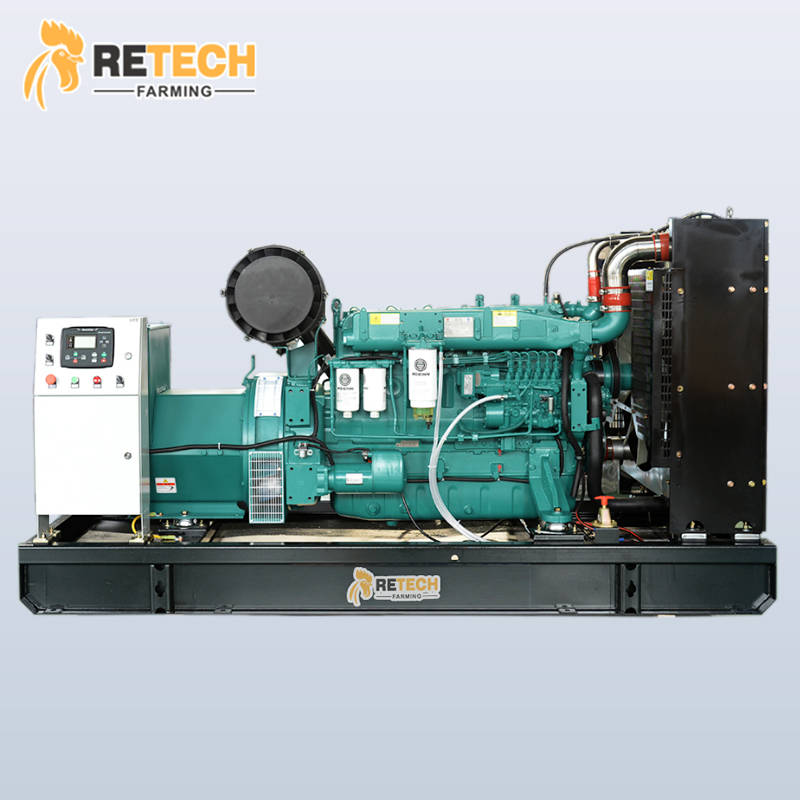

Related Products