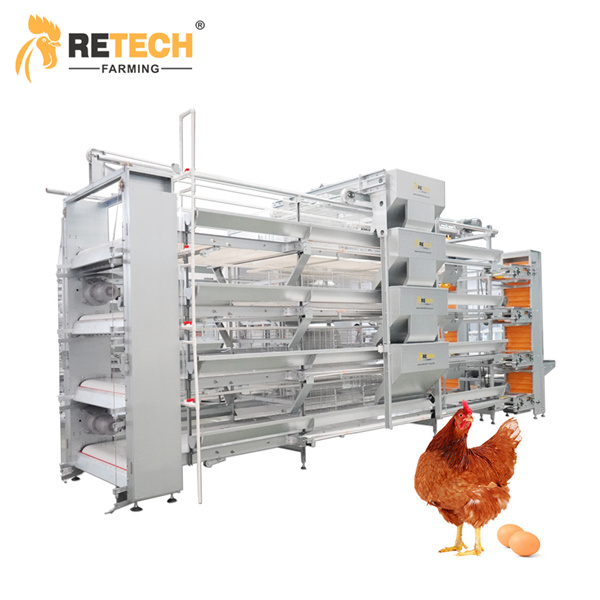

Automated H Type Layer Chicken Cages from Top Manufacturers

When I first came across H Type Layer Chicken Cages, I was impressed by their ability to automate the poultry farming process. These cages are designed for optimal space utilization and enhanced productivity, making them a must-have for any serious chicken farmer. Working with leading manufacturers, I’ve found that these cages not only save labor costs but also improve the overall health and egg production of the birds. With easy access for feeding and maintenance, they streamline daily operations and ensure the chickens are comfortable and stress-free. Besides, using high-quality materials means they’re durable and can withstand the test of time in demanding environments. If you are in the market for an efficient and reliable solution, these automated H Type cages will definitely elevate your poultry business, giving you the edge needed in today’s competitive landscape.

H Type Layer Chicken Cages Supplier Trusted by Pros

When it comes to poultry farming, selecting the right equipment is crucial for maximizing productivity and ensuring animal welfare. Among various options available in the market, H Type Layer Chicken Cages stand out as a highly efficient solution increasingly favored by professionals in the industry. These cages are designed to optimize space, facilitate easy management, and enhance the health and productivity of the birds. Featuring an innovative design that supports natural behaviors while maximizing egg production, these cages are ideal for both small-scale and large-scale operations. One of the key benefits of H Type Layer Chicken Cages is their space-saving structure, enabling farmers to utilize vertical space efficiently. This design not only allows for higher bird stocking density but also simplifies the feeding and egg collection processes. The cages are equipped with modern technology to monitor the health and growth of the chickens, ensuring that farmers can make informed decisions to enhance their operation's efficiency. Additionally, these cages are built with durable materials that withstand harsh conditions, providing long-term value and reliability. For global buyers looking to invest in their poultry operations, the H Type Layer Chicken Cages offer a trusted solution backed by proven performance in various markets. The combination of advanced design, ease of use, and durability makes them a smart choice for anyone looking to elevate their farming practices. As the poultry industry continues to innovate, these cages represent a step forward in achieving sustainable and profitable farming.

H Type Layer Chicken Cages Supplier Trusted by Pros

| Cage Model | Material | Layer Count | Dimensions (L x W x H) | Egg Production Capacity | Weight |

|---|---|---|---|---|---|

| Model H1 | Galvanized Steel | 6 Layers | 200cm x 120cm x 180cm | 1500 Eggs/day | 250 kg |

| Model H2 | Stainless Steel | 8 Layers | 250cm x 120cm x 200cm | 2000 Eggs/day | 300 kg |

| Model H3 | Hot-Dipped Galvanized | 10 Layers | 300cm x 120cm x 220cm | 2500 Eggs/day | 350 kg |

| Model H4 | Plastic Coated Steel | 12 Layers | 350cm x 120cm x 250cm | 3000 Eggs/day | 400 kg |

Related Products