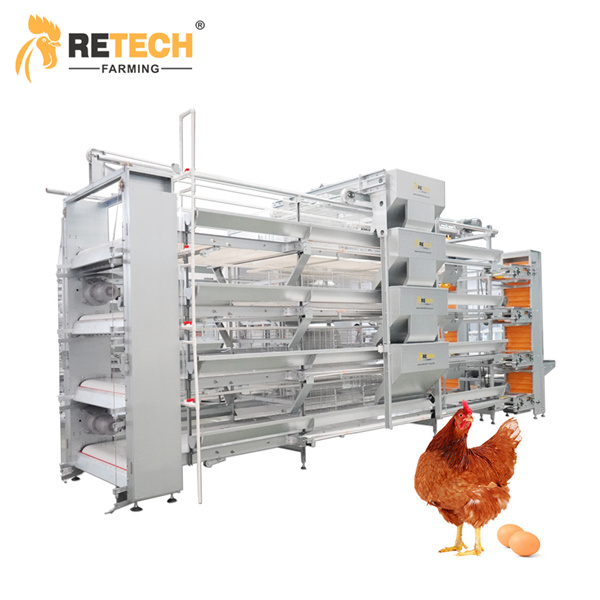

Top Automated Pullet Cages from Leading Manufacturers for Efficient Poultry

When I first came across the automatic pullet cage, I was impressed by how it revolutionizes poultry farming. As a buyer, I see the immense value in choosing an automated system that boosts efficiency and enhances bird welfare. These cages are designed by leading manufacturers who prioritize animal comfort and ease of management. With features like automated feeding, egg collection, and temperature control, they reduce labor costs significantly while maximizing production. I appreciate that this system adapts to various farm sizes, making it perfect for both small-scale and large operations. Transitioning to an automatic pullet cage not only improves operational efficiency but also ensures healthier birds and higher yield—essential factors for me as a B2B purchaser. If you’re striving for a competitive edge in poultry farming, investing in this innovative cage solution is a must. It's time to elevate your farming game with top-notch automated technology!

automatic pullet cage Products in 2025

As the global poultry farming industry evolves, the demand for innovative, efficient, and sustainable solutions continues to grow. In 2025, automatic pullet cages will undoubtedly be at the forefront of this transformation, offering farmers unprecedented advantages in productivity and animal welfare. These advanced systems are designed to optimize space, reduce labor costs, and enhance overall operational efficiency, making them an essential investment for poultry producers worldwide. The integration of smart technology into automatic pullet cages allows farmers to monitor and manage their flocks in real time. With features like automated feeding and watering systems, climate control, and health monitoring, farmers can ensure that their pullets receive the best care while minimizing costs and labor. This technology not only promotes better growth rates and health among the chickens but also contributes to sustainable farming practices by reducing waste and energy consumption. As global demand for poultry continues to increase, investing in automatic pullet cages can help producers stay competitive in the market. By adopting these innovative solutions, farmers can enhance their operational efficiency and improve the quality of their products. As we look to the future, it's clear that automatic pullet cages will play a critical role in the success and sustainability of poultry operations around the world.

Automatic Pullet Cage Products in 2025

| Product Name | Features | Material | Capacity | Dimensions (mm) | Energy Consumption (kW/h) |

|---|---|---|---|---|---|

| Pullet Cage Model A | Automatic feeding, Ventilation system | Galvanized Steel | 500 birds | 2000 x 1200 x 1800 | 3.5 |

| Pullet Cage Model B | Multi-tier design, Automated egg collection | Stainless Steel | 600 birds | 2200 x 1300 x 1900 | 4.0 |

| Pullet Cage Model C | Enhanced biosecurity, Durable construction | Hot-dip Galvanized | 700 birds | 2500 x 1400 x 2000 | 4.5 |

| Pullet Cage Model D | Integrated monitoring system, Space-saving design | Polypropylene | 400 birds | 1800 x 1100 x 1700 | 3.0 |

Related Products