Automatic Chicken House Building: Layer Cage Solutions from Experts

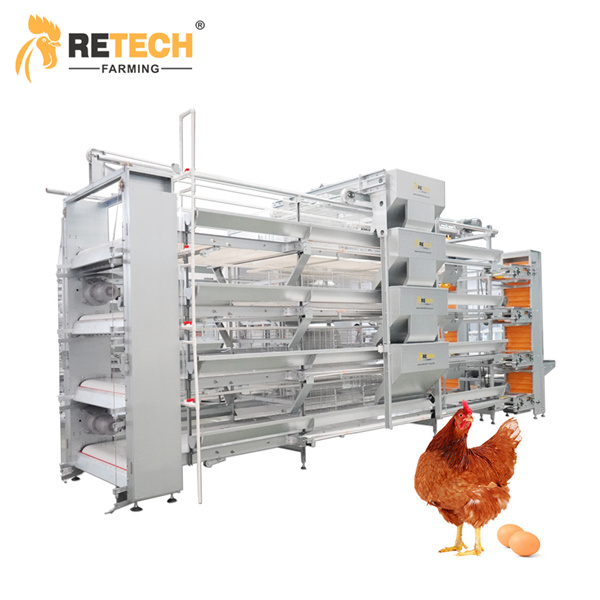

If you’re in the market for efficient chicken house building solutions, I’ve got the perfect option for your poultry farm. Our layer cages are designed for maximum productivity and comfort, ensuring your hens are happy and healthy. As a manufacturer specializing in automatic systems, I understand what it takes to elevate your operations. With features that optimize space and streamline feeding, these cages are perfect for both new and established farms. The durability of our materials guarantees long-lasting use, making this investment worthwhile. Plus, our automatic design reduces labor costs, allowing you to focus on scaling your business. Choose our layer cages, and experience the difference quality can make in your poultry management. Get in touch, and let’s discuss how we can help your farm thrive!

chicken house building,Layer cage Manufacturer For the Current Year

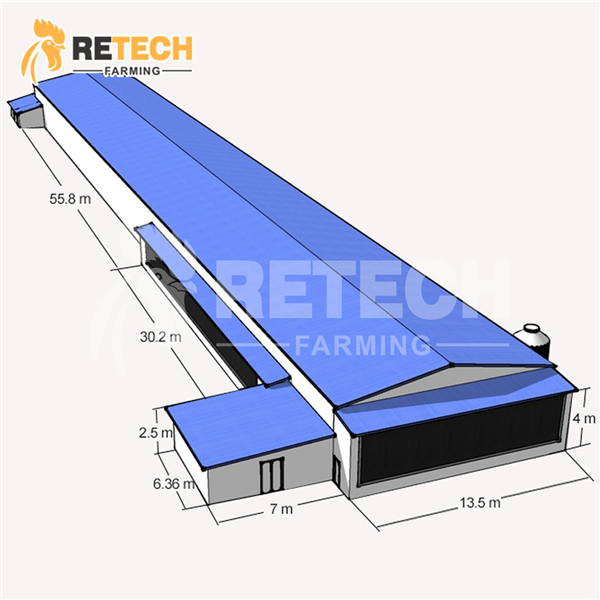

When it comes to building a chicken house, efficiency, and sustainability play crucial roles in ensuring a profitable poultry operation. As the demand for high-quality eggs continues to rise globally, investing in layer cage systems presents an effective solution for modern poultry farmers. These systems maximize space utilization while providing a comfortable living environment for the chickens, promoting their well-being and improving overall productivity. Layer cage manufacturers are now prioritizing innovative designs that enhance food safety, biosecurity, and ease of management. The latest technologies are being employed to create cages that facilitate better egg collection, automated feeding, and waste management. This not only streamlines operations but also addresses the growing concerns about animal welfare and environmental impact within the farming industry. For global buyers, partnering with a reputable manufacturer for high-quality layer cages ensures not only compliance with international standards but also a reliable source of durable and efficient equipment tailored to their specific needs. Investing in modern chicken house building techniques is essential for farmers looking to stay competitive in today's market. With ongoing advancements in technology, manufacturers are committed to delivering solutions that meet the ever-changing demands of poultry farming. As the global market evolves, aligning with innovative and sustainable practices will ultimately lead to greater profitability and success in the poultry industry.

Chicken House Building, Layer Cage Manufacturer For the Current Year

| Model | Material | Capacity (Chickens) | Dimensions (LxWxH) | Features | Warranty (Years) |

|---|---|---|---|---|---|

| Model A | Galvanized Steel | 1000 | 12ft x 6ft x 7ft | Automatic Feeding System | 2 |

| Model B | Plastic | 500 | 10ft x 5ft x 6ft | Ventilation System | 1 |

| Model C | Stainless Steel | 1500 | 14ft x 7ft x 8ft | Heat Insulation | 3 |

| Model D | Wooden Frame | 700 | 11ft x 6ft x 7ft | Eco-Friendly Design | 2 |

| Model E | Aluminum | 1200 | 13ft x 7ft x 8ft | Anti-Corrosion | 5 |

Related Products