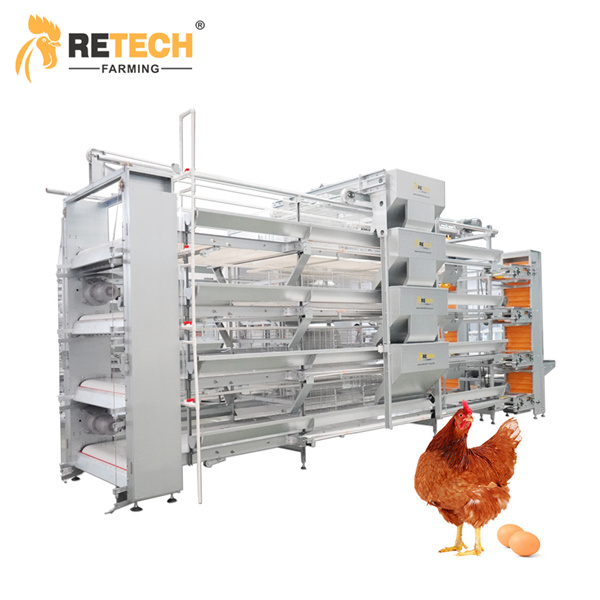

Automated Chicken Egg Layer Cages from Top Manufacturers for Efficient Farming

When it comes to enhancing poultry farming, our Chicken Egg Layer Cages are a game-changer. These automated cages are designed to maximize productivity while ensuring the health and comfort of your hens. I’ve seen firsthand how these systems reduce labor costs and improve egg collection efficiency, making them a favorite among farmers like you. As a manufacturer focused on quality, we ensure our cages meet industry standards while offering scalability for your operation. Whether you’re a small farm or a large-scale producer, our solutions cater to your unique needs. You’ll find that investing in our Chicken Egg Layer Cages not only boosts your output but also simplifies management. Let's talk about how we can support your business growth with our innovative and reliable products.

Chicken Egg Layer Cages Application From Concept to Delivery

The poultry industry is witnessing transformative advancements, particularly in the realm of chicken egg layer cages. Understanding the journey from concept to delivery can be crucial for global buyers looking to optimize their operations. The initial phase involves comprehensive research and development, where innovative designs are crafted to enhance hen welfare while maximizing egg production efficiency. These cages are engineered to ensure adequate space, ventilation, and access to feed and water, addressing both the birds' needs and the operational goals of farmers. Once the design is finalized, the manufacturing process prioritizes durability and compliance with international quality standards. Employing cutting-edge technology and high-grade materials ensures that these cages withstand harsh environmental conditions, providing a long-lasting solution for egg production. Quality control measures are implemented at every stage, from sourcing materials to final assembly, guaranteeing a product that meets the high expectations of global markets. Finally, the delivery phase focuses on efficient logistics and support services. Timely and safe transportation is essential to ensure that buyers receive their products in optimal condition. Additionally, after-sales support, including installation guidance and maintenance tips, enhances the overall customer experience. By streamlining the entire process from concept to delivery, poultry farmers can look forward to increased productivity and sustainable operations in the competitive global market.

Chicken Egg Layer Cages Application From Concept to Delivery

| Dimension | Description | Material | Capacity | Features |

|---|---|---|---|---|

| Standard Cage | Basic chicken egg layer cage suitable for small farms | Galvanized Steel | Up to 40 hens | Durable, Easy to Clean |

| Tier Cage | Multi-level cage system for higher efficiency | Stainless Steel | Up to 120 hens | Space-saving, Automated Feeding System |

| Battery Cage | High-capacity battery cage for commercial farms | Electro-galvanized Steel | Up to 400 hens | Optimal Egg Production, Climate-Controlled |

| Nesting Cage | System designed to promote natural nesting behavior | Plastic and Metal | Up to 60 hens | Natural Behavior Supported, Easy Access for Egg Collection |

| Automated Control System | Smart system for monitoring environmental conditions | Electrical Components | N/A | Remote Monitoring, Alerts for Anomalies |

Related Products