Automated Broiler Chicken Equipment from Top Manufacturers

As someone who’s spent years in the broiler chicken industry, I get how crucial it is to have the right equipment. Our automated broiler chicken equipment stands out because it streamlines processes, ensuring optimum efficiency and productivity in your operations. I’ve worked closely with leading manufacturers to create solutions that address common challenges faced by poultry growers, making sure each piece of equipment meets industry standards and delivers superior performance. The technology behind these systems really makes a difference, allowing for better monitoring and management of your flock. Plus, with automation, you can reduce labor costs and minimize human error. I know you’re looking to enhance your operations, and investing in our equipment can set you on that path to success. It’s more than just equipment; it’s about giving you the tools to thrive in a competitive market. Let’s elevate your poultry farming together!

Broiler Chicken Equipment Delivers Unmatched Quality Supplies the World\u2019s Top Brands

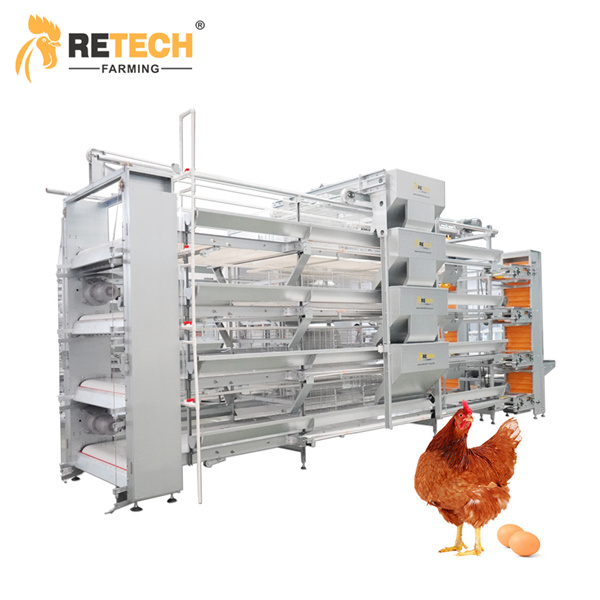

In the rapidly evolving poultry industry, maintaining the highest standards of quality is essential for producers aiming to meet global demand. Advanced broiler chicken equipment plays a pivotal role in ensuring optimal growth conditions, enhancing overall productivity, and minimizing costs. By integrating cutting-edge technology with proven methodologies, modern poultry equipment delivers unparalleled efficiency, supporting various phases of chicken rearing from hatchery to processing. As the world’s leading brands continue to prioritize animal welfare and biosecurity, the reliable equipment they choose becomes crucial. From climate control solutions to automated feeding systems, each component is designed to create an environment conducive to healthy growth. Investing in high-quality equipment not only boosts output but also aligns producers with global standards and consumer expectations, fostering trust and reputation in international markets. Furthermore, as sustainability becomes a key focus in agriculture, many innovative solutions aim to reduce environmental impact while enhancing production capabilities. The adoption of energy-efficient systems and waste management technologies not only supports responsible farming practices but also drives down operational costs. By focusing on quality and sustainability, buyers can ensure they are equipped to thrive in a competitive landscape, positioning themselves as leaders in the global poultry sector.

Broiler Chicken Equipment Delivers Unmatched Quality Supplies the World’s Top Brands

| Equipment Type | Function | Material | Capacity (units/hour) | Energy Consumption (kWh) |

|---|---|---|---|---|

| Broiler Feeder | Feed distribution | Galvanized steel | 200 | 1.5 |

| Watering System | Water supply | Plastic/metal | 150 | 0.8 |

| Heating System | Temperature control | Steel | 300 | 3.0 |

| Ventilation Fan | Air circulation | Aluminum | 250 | 2.0 |

| Cage System | Space utilization | Galvanized steel | 1000 | 1.2 |

Related Products