Automated Baby Chick Cages from Top Manufacturers for Easy Care

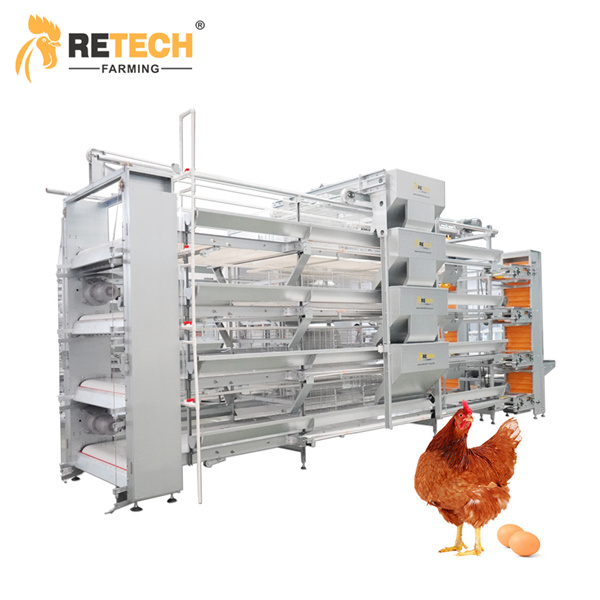

When setting up my poultry operation, finding the right baby chick cages was crucial. I turned to automated solutions that streamline the care process, allowing me to focus on growth rather than manual tasks. These cages are designed with precision and durability in mind, made by leading manufacturers in the industry. They offer excellent ventilation and easy access, keeping my chicks healthy and well-cared-for. The automation features make feeding and monitoring simpler than ever, enhancing my productivity and ensuring optimal conditions for my baby chicks. If you’re like me and want the best for your poultry business, investing in quality baby chick cages can truly make a difference. The right choice can transform your operations, elevate your productivity, and support your business growth—it's an investment in your success!

Baby Chick Cages Application Ahead of the Curve

As the poultry industry evolves, innovative solutions are essential to keep pace with changing demands. The application of baby chick cages is not just a trend; it represents a significant advancement in farming practices. Designed with the unique needs of young chicks in mind, these cages offer an ideal environment for growth and development. Proper ventilation, temperature control, and space for movement contribute to healthier chicks, ultimately leading to improved production rates. By investing in advanced chick cage technology, farmers can enhance biosecurity measures and reduce the risk of disease transmission. These cages provide a clean and controlled environment, minimizing contact with outside pathogens. Moreover, the efficient design allows for easy access to feed and water, promoting optimal nutrition for the chicks. This not only ensures healthy growth but also contributes to quicker turnaround times for farmers, enhancing overall operational efficiency. Global buyers are increasingly seeking these innovative solutions to elevate their farming practices. The integration of technology in baby chick cages not only meets animal welfare standards but also aligns with sustainable farming goals. As the poultry market expands, adopting cutting-edge equipment is crucial for staying competitive and maximizing productivity. Embracing these advancements is a key step for farmers looking to thrive in a rapidly changing industry.

Baby Chick Cages Application Ahead of the Curve

| Cage Type | Material | Dimensions (cm) | Max Capacity (Chicks) | Ventilation Type | Applicable Age (Days) |

|---|---|---|---|---|---|

| Standard Cage | Plastic | 100 x 60 x 50 | 20 | Open | 0-14 |

| Advanced Vent Cage | Metal | 120 x 70 x 55 | 25 | Mesh | 0-21 |

| Eco-Friendly Cage | Recycled Plastic | 110 x 65 x 50 | 18 | Hooded | 0-14 |

| Expandable Cage | Wood | 130 x 75 x 60 | 30 | Adjustable | 0-28 |

Related Products