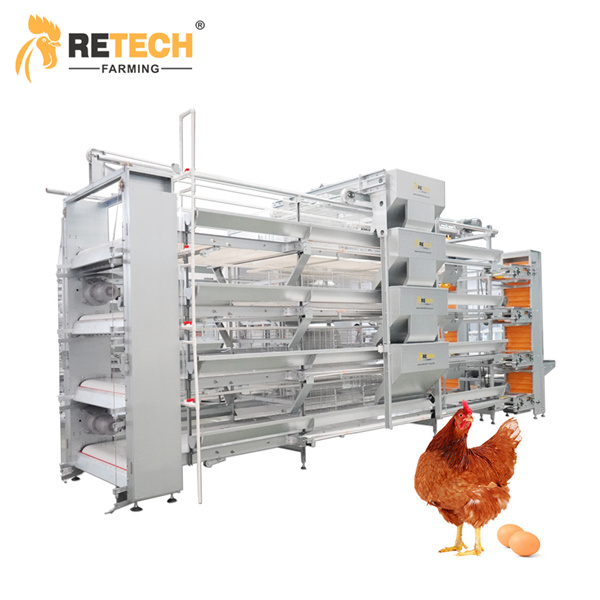

Efficient Automatic Poultry Layer Cage Design by Leading Manufacturer

When it comes to enhancing productivity in poultry farming, our Poultry Layer Cage Design stands out as a game-changer. As a manufacturer specializing in automatic systems, I understand the challenges faced by poultry producers. This design not only maximizes space but also ensures the health and well-being of the hens, leading to higher egg production. Our cages are crafted with durable materials that withstand the rigors of daily use, ensuring longevity and reliability. The automatic feeding and watering systems minimize labor costs and improve efficiency, allowing farmers to focus on what truly matters. I take pride in offering customizable solutions to meet specific operational needs, making every installation a perfect fit for your farm. With our innovative designs, I’m confident you will see a rapid return on investment. Elevate your poultry operations and streamline your processes with our state-of-the-art cages—let’s take your farm to the next level!

Poultry Layer Cage Design Application Sets the Industry Standard

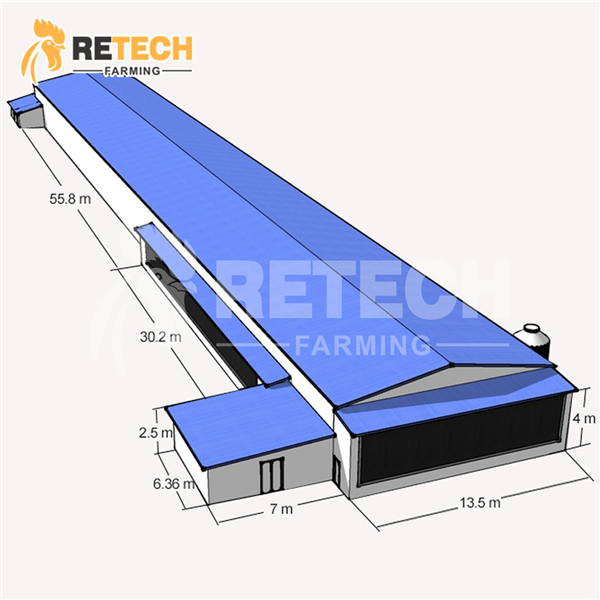

In the evolving landscape of poultry farming, the design and application of layer cages have become crucial in setting industry standards for efficiency and sustainability. Modern layer cage systems are engineered to optimize space and enhance the welfare of hens while maximizing egg production. These innovative solutions not only facilitate better management practices but also ensure compliance with global animal welfare regulations. By adopting advanced technologies and materials, today's poultry layer cages offer improved ventilation, hygiene, and accessibility, which contribute to healthier birds and higher yield rates. Features such as automated feeding and egg collection systems significantly reduce labor costs and enhance operational efficiency. Moreover, with a focus on sustainability, these designs integrate energy-saving mechanisms that lower the overall environmental impact of poultry farming. As global demand for poultry products continues to rise, investing in state-of-the-art layer cage systems is essential for producers aiming to stay competitive. By aligning with industry standards, farmers can ensure their operations are not only profitable but also responsible and future-proof.

Poultry Layer Cage Design Application Sets the Industry Standard

| Layer Cage Type | Material | Area (m²) | Capacity (birds) | Ventilation System | Egg Collection Method |

|---|---|---|---|---|---|

| Battery Cage | Galvanized Steel | 5.0 | 80 | Natural Ventilation | Automatic Conveyor |

| Aviary System | Stainless Steel | 10.0 | 120 | Forced Ventilation | Manual Collection |

| Traditional Cage | Welded Wire | 4.0 | 60 | Natural Ventilation | Manual Collection |

| Cage-Free System | Reinforced Plastic | 15.0 | 150 | Hybrid Ventilation | Automatic Conveyor |

Related Products