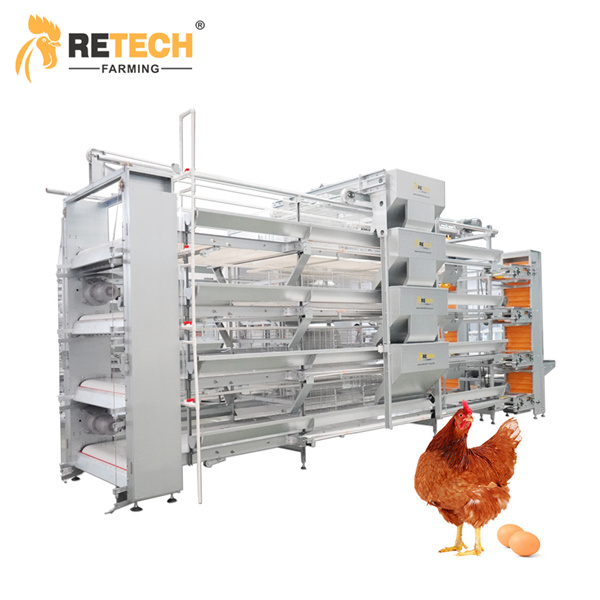

Automatic Broiler Battery Cage Manufacturer for Optimal Chicken Equipment

As a poultry equipment enthusiast, I understand how crucial it is for businesses like yours to have reliable solutions. Our broiler battery cage systems are designed to maximize productivity while ensuring the welfare of your chickens. I’ve seen firsthand the difference that automatic feeders and water systems make in daily operations. These features save time and labor, allowing you to focus on scaling your production. As a manufacturer dedicated to quality, we pride ourselves on our innovative designs that cater to both small-scale and large-scale operations. With durable materials and easy assembly, our equipment stands out in the market. By partnering with us, you’re not just getting chicken equipment, but a commitment to enhancing your poultry farming experience. Let’s take your production to the next level together!

chicken equipment,broiler battery cage Where Innovation Meets 2025 Global Reach

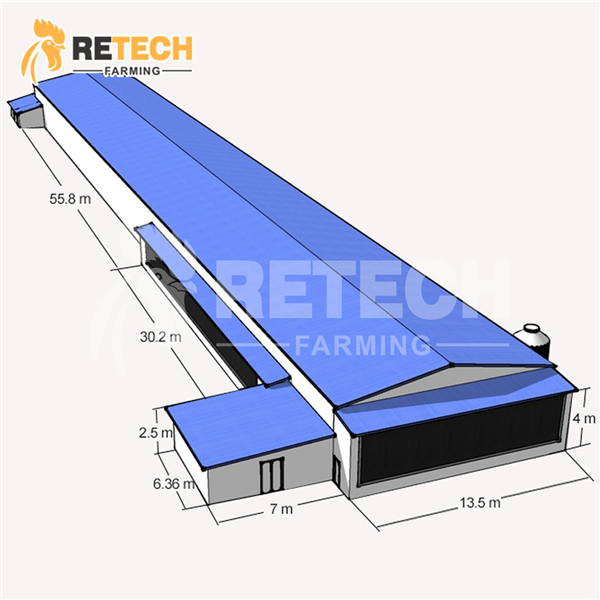

In the ever-evolving landscape of poultry farming, innovation is key to staying ahead. As we approach 2025, the demand for efficient and sustainable chicken equipment has surged, particularly in the realm of broiler battery cages. These advanced systems not only optimize space but also enhance the welfare of the birds, ensuring healthier growth and higher yield. By leveraging cutting-edge technology, farmers can significantly reduce labor costs while maintaining optimal production standards. The global market for poultry equipment is expanding rapidly, driven by increasing consumer demand for protein and a higher focus on sustainable farming practices. Our innovative broiler battery cages are designed with adaptability in mind, allowing farmers around the world to meet specific regional requirements while also complying with international standards. This flexibility positions these systems as the ideal choice for enterprises looking to enhance their operational efficiency and product quality. As we look towards a global reach in 2025, it’s essential for poultry producers to invest in equipment that not only boosts productivity but also aligns with the future of sustainable agriculture. Embracing innovation in chicken farming equipment sets the stage for a more resilient industry that can meet the challenges of tomorrow while delivering exceptional results today.

Chicken Equipment - Broiler Battery Cage: Where Innovation Meets 2025 Global Reach

| Feature | Description | Benefits | Sustainability |

|---|---|---|---|

| Automated Feeding System | A system that automatically distributes feed to the broilers. | Reduces labor costs and ensures consistent nutrition. | Minimizes feed wastage with precise distribution. |

| Climate Control | Integrated systems to maintain optimal temperature and humidity. | Enhances growth rates and overall bird health. | Energy-efficient systems contribute to lower carbon footprint. |

| Space Optimization | Stacked design allows for higher density housing of birds. | Maximizes production per square foot. | Efficient use of land resources. |

| Waste Management System | Automated systems for waste collection and processing. | Improves hygiene and reduces manual labor. | Recycles waste into compost for sustainable farming. |

| Monitoring Technology | Real-time monitoring of bird health and equipment performance. | Enhances productivity and timely interventions. | Data-driven decisions lead to sustainable practices. |

Related Products