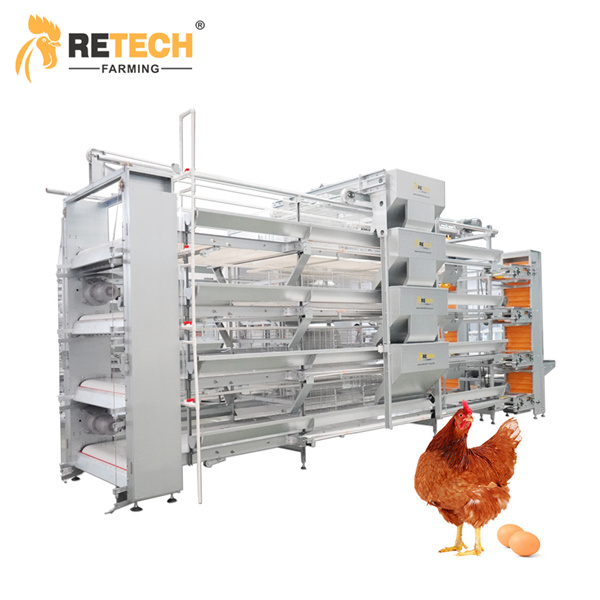

Top Automatic Chicken Broiler Cage from Leading Manufacturers

As a B2B purchaser, I know the importance of investing in efficient and reliable equipment for poultry farming. The Automatic Chicken Broiler Cage is a game changer for me. This system not only maximizes space but also automates feeding and watering, which saves me a ton of time. I appreciate that it's designed by a top-tier manufacturer known for their innovative approach and quality. The automatic features make it easy to manage a large flock without constant supervision, allowing me to focus on other critical aspects of my business. With robust materials and smart design, these cages promise to enhance growth rates and improve overall bird welfare. If you're aiming to boost your poultry production and reduce labor costs, I highly recommend considering this Automatic Chicken Broiler Cage as a solid investment for your operations. It’s a smart choice I won’t regret!

Automatic Chicken Broiler Cage Factory-Direct Excellence Where Service Meets Innovation

In the ever-evolving poultry industry, ensuring optimal production while minimizing operational costs is paramount. Automatic chicken broiler cages have revolutionized the way farmers approach poultry farming. These innovative systems not only enhance the welfare of the birds but also maximize efficiency in feed conversion and space utilization. With factory-direct excellence, farmers can access high-quality products that meet rigorous industry standards without the added costs typically associated with middlemen. Leveraging advanced technology, modern broiler cages enable precise control over environmental conditions, ensuring that chickens thrive in a safe and healthy habitat. Such advancements also facilitate labor efficiency, allowing farmers to manage larger flocks with reduced manual intervention. The integration of intelligent design features further ensures that routine care tasks are simplified, making it easier to maintain high standards of hygiene and disease prevention. For global buyers seeking reliable solutions for their poultry operations, investing in automatic broiler cages represents not just an upgrade in equipment, but a commitment to embracing sustainable farming practices. As the demand for poultry products continues to rise, equipping facilities with innovative technologies will not only enhance productivity but also bolster profitability in a competitive market.

Automatic Chicken Broiler Cage Factory-Direct Excellence Where Service Meets Innovation

| Dimension | Specification | Material | Capacity | Features |

|---|---|---|---|---|

| 2m x 1m x 1.5m | 3 Tiers, 6 Compartments | Galvanized Steel | 120 Birds | Automatic feeder and waterer, easy cleaning |

| 2.5m x 1.2m x 1.8m | 5 Tiers, 10 Compartments | Stainless Steel | 200 Birds | Temperature control, durable design |

| 3m x 1.5m x 2m | 6 Tiers, 12 Compartments | High-strength Plastic | 300 Birds | Environmentally friendly, energy-efficient |

| 1.8m x 1m x 1.4m | 4 Tiers, 8 Compartments | Cold-rolled Steel | 150 Birds | Easy assembly, space-saving design |

Related Products