In hot, humid regions like the Philippines, Indonesia, and Thailand, the accumulation of chicken manure, which causes fly breeding and foul odor, is a major headache for farmers. It not only affects the health of the flock but can also cause neighborhood conflicts. As a poultry farming equipment manufacturer and solutions provider, Retech Farming offers a series of effective strategies to help farmers minimize these issues.

Why is chicken manure a particularly prominent problem in hot regions?

1. High temperatures promote the rapid decomposition of organic matter, producing large amounts of gases such as ammonia and hydrogen sulfide, as well as volatile organic compounds (VOCs).

2. High humidity promotes fly egg laying and larval growth. The longer manure is exposed, the more severe the fly infestation.

3. Exposed manure, improper storage areas, and untimely removal directly amplify neighborhood perceptions of odor and flies.

Retech Farming’s chicken manure composting solutions

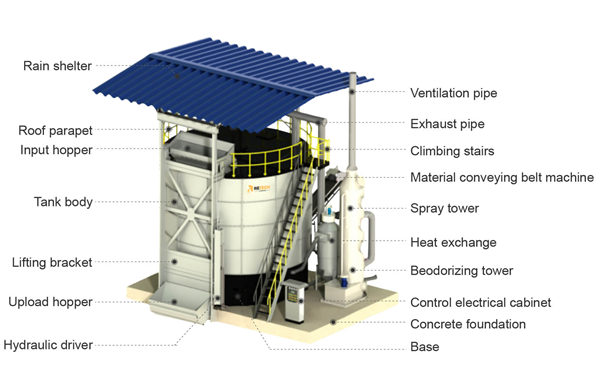

1. Use efficient chicken manure treatment equipment – Retech energy-saving fermentation tanks

Automated chicken manure treatment equipment is key to solving the problem of manure accumulation. Our energy-saving fermentation tanks and automated manure removal systems can quickly and effectively process chicken manure, reducing its residence time in the chicken house and thus reducing the potential for fly breeding.

How does it work?

1. Rapid collection and closed processing

1.1. The equipment seamlessly integrates with your automated manure removal system, transferring chicken manure directly into the completely sealed fermentation tank.

1.2. It isolates odors at the source and prevents flies from contacting the manure, thus disrupting their breeding chain.

2. High-temperature aerobic fermentation for efficient pest control

2.1. Within the tank, forced oxygen supply and a stirring system create an optimal environment for beneficial microorganisms.

2.2. The core fermentation temperature can quickly rise to 60-70°C or even higher. This high-temperature process:

> Completely kills fly eggs, maggots, and various pathogens and parasites. >. Rapidly decomposes odor-causing organic molecules, eliminating odors from the fermentation tank.

> Turning waste into treasure: After approximately 7-10 days of processing, chicken manure is transformed into non-toxic, odorless, and high-quality organic fertilizer.

> You can use it directly on your farm or package and sell it, creating a new source of income for your farm.

2. Choose a modern ventilation system.

A good ventilation system can effectively reduce the temperature and humidity inside the chicken house, minimizing odors produced by the decomposition of chicken manure. Retech Farming’s tunnel ventilation system, which includes fans, ventilation louvers, air inlets, wet curtains, and other ventilation equipment, ensures air circulation and improves the chicken house environment.

3. Regular Cleaning and Disinfection

Clean the chicken house and surrounding area regularly. A thorough cleaning and disinfection is recommended weekly, especially during hot weather. Using an environmentally friendly disinfectant can effectively kill bacteria and fly eggs, and reduce odor.

4.Choose More Efficient Cage Equipment

Cage Equipment: Automated H-type chain-type broiler harvesting cages with separate manure removal and discharge systems reduce the amount of manure that falls on the birds and the time it remains in the cages. Combined with a manure collection system, this significantly reduces fly breeding and odor generation.

Automated Watering and Feeding System: Controllable water intake and feed ratios prevent waste and moisture, reduce the moisture content of manure, and slow fermentation.

5. Choose the right feed.

The quality and composition of feed also affect the odor of chicken manure. Choosing easily digestible feed can reduce ammonia and other odorous components in chicken manure.

6. Scientific manure management.

Establishing a scientific manure management system on the farm, including manure collection, storage, and treatment, can effectively reduce manure accumulation. It is recommended to promptly transfer chicken manure to a dedicated disposal area to avoid prolonged storage in the chicken house.

7. Locate the chicken farm away from residential areas.

Locating the chicken farm on open land away from people can effectively reduce complaints and misunderstandings.

Don’t let chicken manure problems limit your farming development!

For farmers and investors in high-temperature environments, Retech Farming is your most reliable partner. With our automated farming equipment and intelligent chicken manure treatment solutions, you can not only effectively address prominent issues like flies and odor, avoiding neighborhood complaints, but also significantly improve farming efficiency, reduce operating costs, and achieve sustainable, environmentally friendly, modern farming.

Welcome to Retech Farming

For more information about our fermentation equipment or to get professional advice, contact our customer service team now!

Email:director@retechfarming.com

Post time: Oct-10-2025