Automated Hot Galvanization Poultry Equipment from Trusted Manufacturers

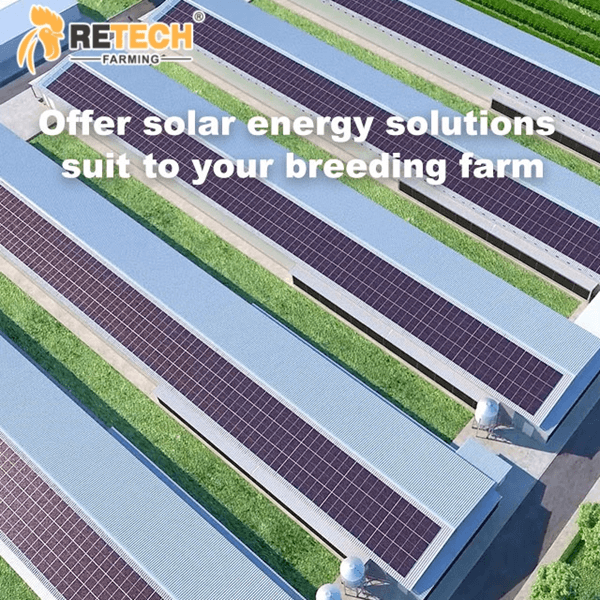

When it comes to enhancing your poultry operations, our Hot Galvanization Poultry Equipment is a game-changer. I’ve seen how automated solutions can transform the efficiency of farms, reducing labor costs while increasing productivity. This durable equipment is manufactured with precision to withstand the harshest conditions, ensuring long-lasting performance. I’ve worked closely with several manufacturers who understand the unique needs of modern poultry businesses. Each component is designed to integrate seamlessly into your existing systems, bringing you the best in technology and reliability. With our equipment, you can focus more on nurturing your flock and less on maintenance worries. Investing in hot galvanization ensures your equipment is resistant to rust and corrosion, ultimately saving you money in the long run. Let’s elevate your poultry farming experience together with our innovative and reliable solutions!

Hot Galvanization Poultry Equipment in 2025 Factory-Direct Excellence

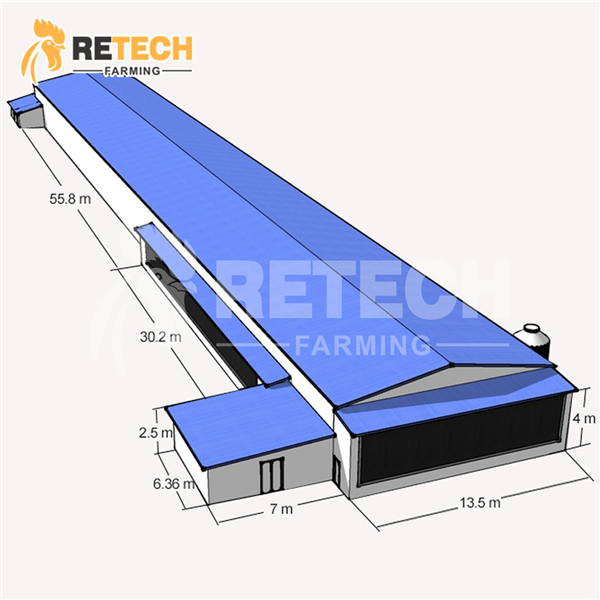

As we look ahead to 2025, the demand for high-quality poultry equipment continues to rise globally. The hot galvanization process is gaining attention as it offers exceptional durability and resistance to corrosion, making it ideal for poultry farming environments. With the increasing need for sustainable and efficient farming solutions, investing in top-tier poultry equipment can streamline operations and enhance productivity. For global buyers, factory-direct excellence ensures not only cost-effectiveness but also the assurance of superior quality control. Direct purchasing from manufacturers allows access to the latest innovations in poultry equipment, designed to improve animal welfare and meet rising regulatory standards. The benefits of advanced technologies in feeding, watering, and climate control systems are essential for maximizing the health and growth of poultry. As the industry evolves, the importance of sourcing reliable and efficient equipment cannot be overstated. Future-proofing your poultry operation with cutting-edge, hot-galvanized solutions will position your business at the forefront of the market, ensuring sustainability and profitability in an ever-competitive landscape. Embrace the future of poultry farming by investing in equipment that meets the highest standards of quality and performance.

Hot Galvanization Poultry Equipment in 2025 Factory-Direct Excellence

| Equipment Type | Material | Capacity (Units) | Operation Method | Durability (Years) |

|---|---|---|---|---|

| Automatic Feeder | Galvanized Steel | 500 | Electric | 10 |

| Broiler Cage | Galvanized Wire | 1000 | Manual | 15 |

| Nipple Drinker | Plastic/Metal | 300 | Gravity | 8 |

| Heat Lamp | Aluminum | 200 | Electric | 5 |

| Incubator | High Strength Plastic | 240 | Automatic | 10 |

Related Products