Automatic Broiler Cages For Sale - Trusted Manufacturer Quality Solutions

As a poultry farmer, I know how crucial it is to have the right equipment for optimal production. That's why I’m excited to share our automatic broiler cages for sale. These cages are designed to maximize space and efficiency, making it easier than ever to manage your flock. Our line of broiler cages comes directly from a top manufacturer, ensuring quality and durability. With features like adjustable feeding systems and integrated watering solutions, you can reduce labor costs while boosting your production rates. Whether you're just starting out or looking to upgrade your existing setup, these cages are a fantastic investment. They not only save you time but also contribute to healthier birds and better yields. Don’t miss out on the opportunity to elevate your poultry operation—check out our automatic broiler cages today!

Broiler Cages For Sale Application From Concept to Delivery

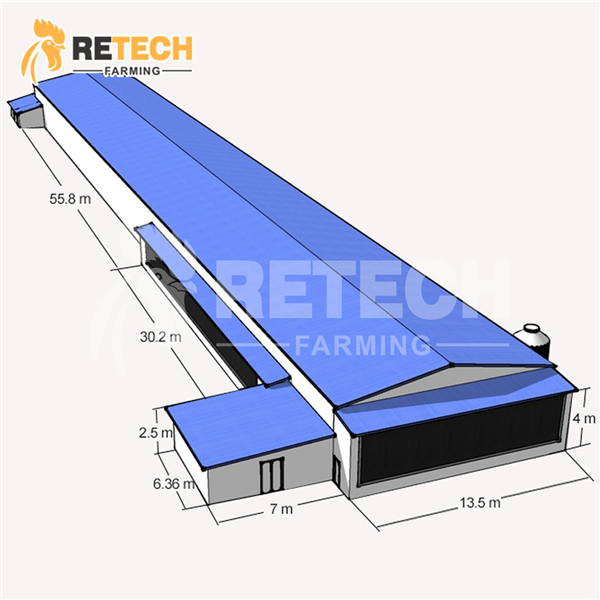

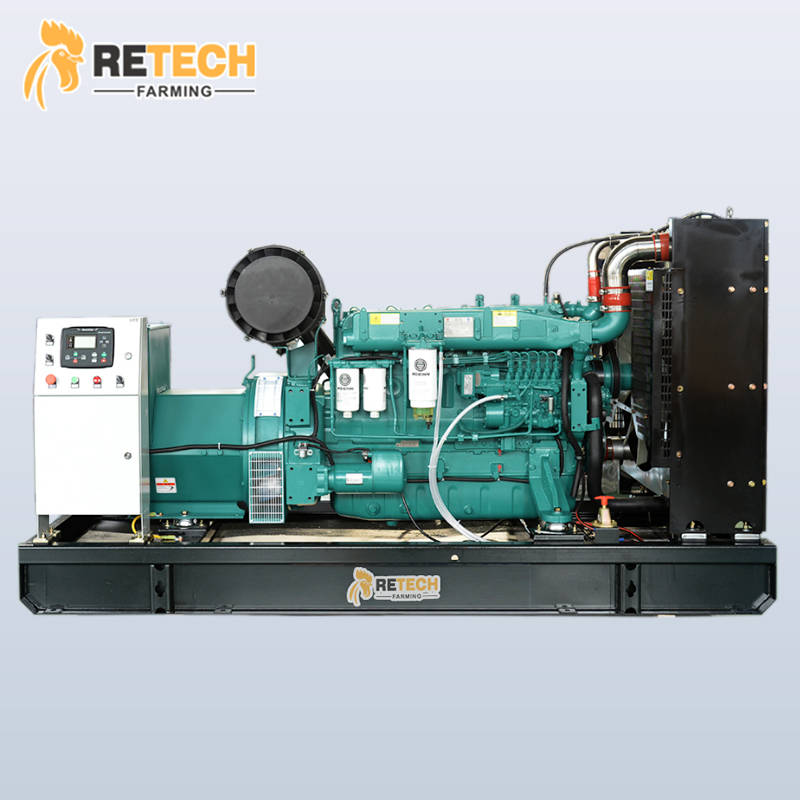

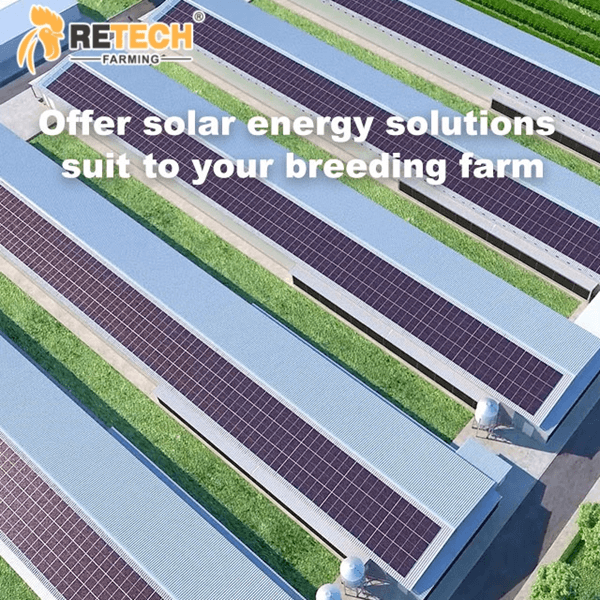

In the poultry industry, the efficiency of broiler production is significantly influenced by the equipment used, particularly in housing and management practices. Broiler cages play a crucial role in enhancing the health and growth rate of chickens, leading to increased yields and profitability for farmers. From concept to delivery, it is essential to choose a reliable partner who can provide high-quality, innovative cage systems tailored to meet the specific needs of your operation. When sourcing broiler cages, it is important to consider factors such as design, material, and capacity. Modern cage systems are designed to maximize space while ensuring optimal airflow, reducing stress on the birds, and facilitating easy access for management personnel. With the advent of technology, many manufacturers now offer automated systems to streamline feeding, cleaning, and monitoring, ultimately saving time and labor costs. Furthermore, investing in durable materials can reduce long-term operational expenses, making the right choice a significant factor in your overall business success. Delivery is another vital aspect of the procurement process. A smooth and timely delivery ensures that your production schedule remains uninterrupted. It is crucial to assess potential suppliers on their ability to meet deadlines and provide post-purchase support. Collaborating with a partner who understands your needs from the very beginning and is committed to delivering quality products will empower your business to thrive in the competitive poultry market.

Broiler Cages For Sale Application From Concept to Delivery

| Application Stage | Description | Time Frame | Key Considerations |

|---|---|---|---|

| Concept Development | Initial design ideas and feasibility studies. | 1-2 weeks | Market research, target customer needs. |

| Design Finalization | Finalize technical specifications and cage layout. | 2-3 weeks | Regulations, safety standards. |

| Production Planning | Preparation of production timeline and resources. | 1-2 weeks | Material sourcing, machine availability. |

| Manufacturing | Production of broiler cages based on specifications. | 4-6 weeks | Quality control, labor management. |

| Quality Assurance | Inspection and testing of finished products. | 1 week | Compliance with industry standards. |

| Delivery | Transportation of cages to the customer's location. | 1-2 weeks | Logistics, delivery scheduling. |

| Installation | Setting up cages on-site according to layout. | 1 week | Site preparation, staff training. |

Related Products